Overview

I designed, machined and assembled a scribe block as part of an HND workshop build, taking it from marked-out stock to a finished, inspected tool. I produced the rocker, clamp, sleeve, spindle, locking and adjusting screws, clamp nut, pivot screw, base and scribe, then integrated the supplied dowel, spring, ball bearing and threadlocker. Key operations included templating and filing an R100 profile, drilling and tapping M8×1.25/M5×0.8 threads, turning, knurling and threading on the lathe, heat-treating a silver-steel scribe, and vertical/horizontal milling a cast-iron base with slots and a V-groove. I resolved a threading mismatch by re-tapping and re-threading affected parts, then verified dimensions against drawings and assembled with controlled preload and Loctite. The final tool met functional requirements; my main lesson was tightening measurement discipline to keep all features within tolerance on first pass.

Process

- Scope & components: Manufactured 10 parts (base, rocker, clamp, locking screw, clamp nut, sleeve, adjusting screw, spindle, pivot screw, scribe) and integrated supplied hardware (dowel pin, spring, ball bearing, Loctite 242).

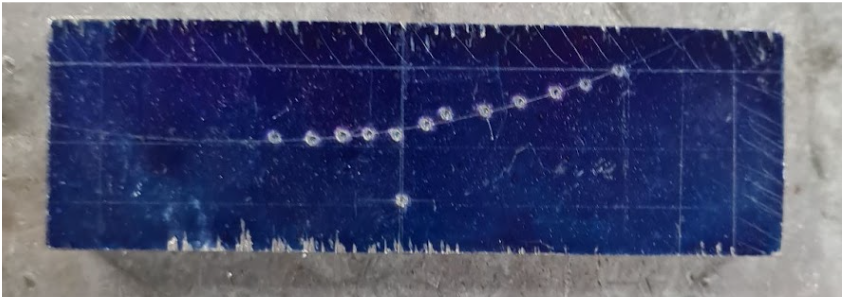

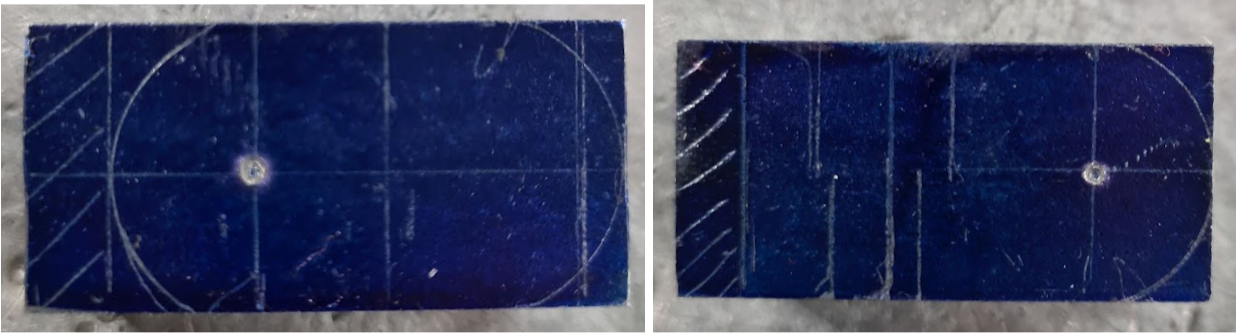

- Marking-out & profiling: Created datums, templated and filed the R100 rocker profile; used number/letter drills for tapped holes.

- Drilling & tapping: Drilled with centre drills then stepped bits; tapped M8×1.25 and M5×0.8 threads with taper/plug/bottom taps.

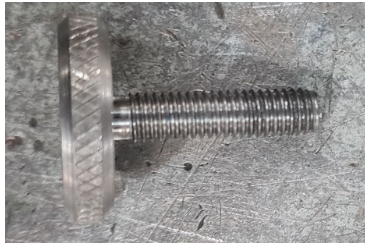

- Lathe work: Turned/undercut/threaded the spindle; produced sleeve, locking screw, adjusting screw (including knurling and chamfers); drilled cross-holes on the drill press.

- Scribe manufacture: Ground, heat-treated (oil quench / temper to straw) and bent to R20 from 3 mm silver steel.

- Milling (base): Faced cast-iron base; horizontal mill for slot/step (71 RPM, 16 mm cutter), drilled 6 mm/9 mm/O holes, tapped M8×1.25, then vertical mill for a 1 mm-deep V-groove.

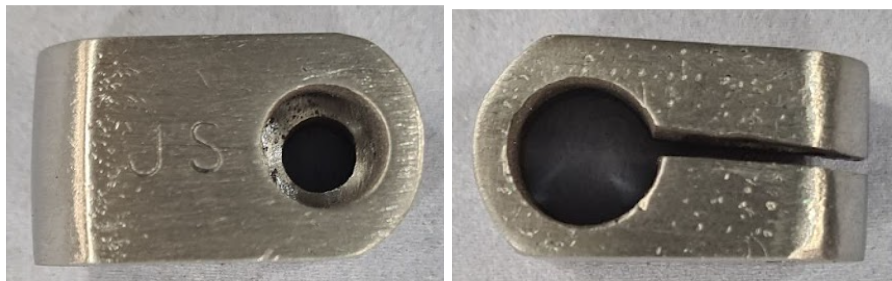

- Issue resolution: Corrected spindle/rocker fit by re-tapping/re-threading; adjusted an O-drilled pocket so the ball bearing seated correctly.

- Inspection & assembly: Verified critical dimensions/surface finish with vernier gauges and charts; preloaded spring/ball, applied Loctite to the pivot screw, and completed assembly.

Outcomes

- Functional tool: Final assembly operated as intended with all components interfacing correctly.

- Dimensional results: Most features met targets; a few measurements were marginally out (≈1–2 mm) but acceptable for function and waste reduction.

- Problem-solving: Resolved thread mismatch (spindle ↔ rocker) via re-tapping/re-threading; corrected bearing seat—capturing practical fit/finish lessons.

- Manufacturing breadth: Demonstrated marking-out, drilling/tapping, turning/knurling/threading, heat treatment, and vertical/horizontal milling—including V-groove and stepped features.

- Safety & discipline: Followed workshop PPE and machine-safety protocols; key takeaway was tightening measurement discipline to keep all features within tolerance on first pass.