Overview

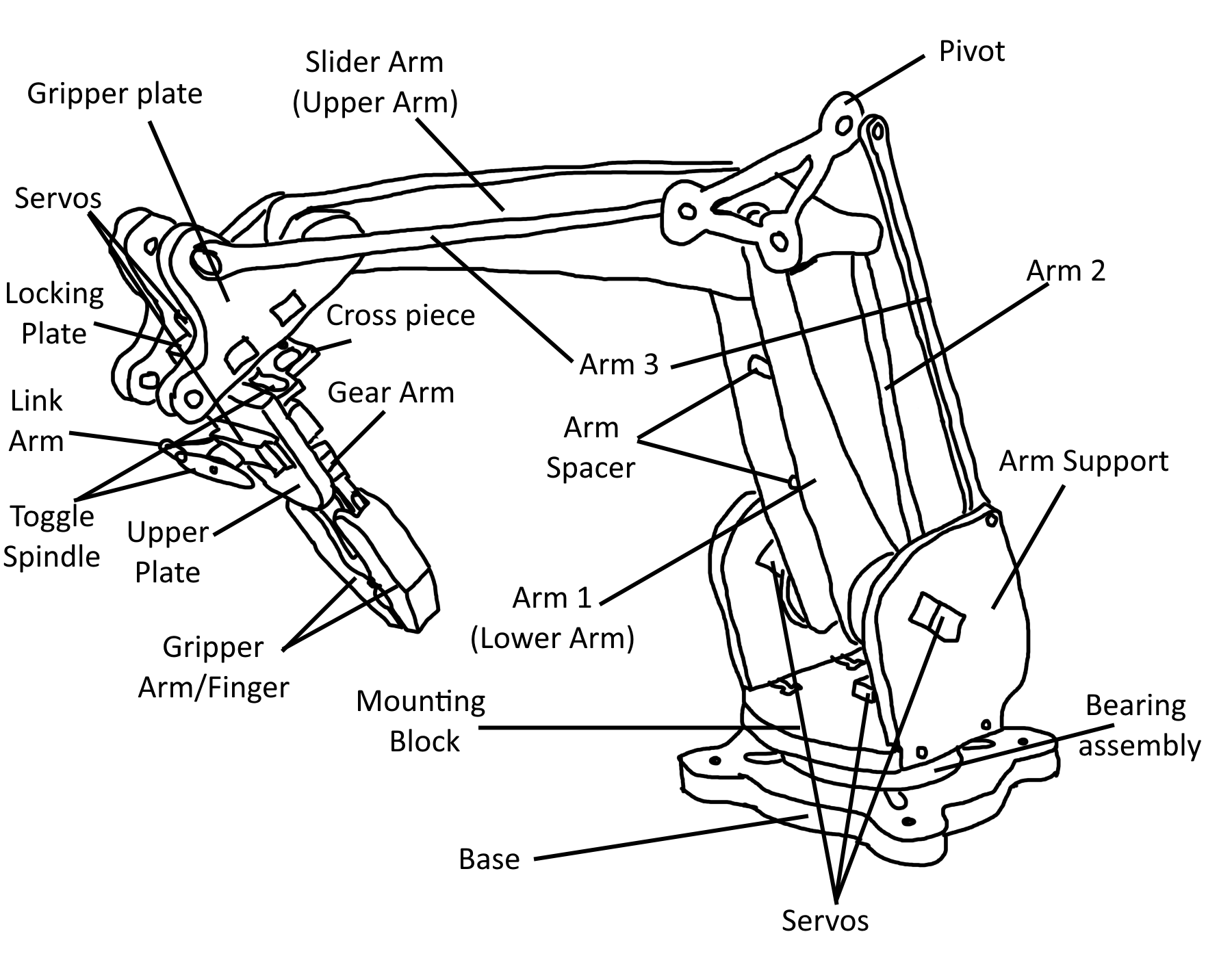

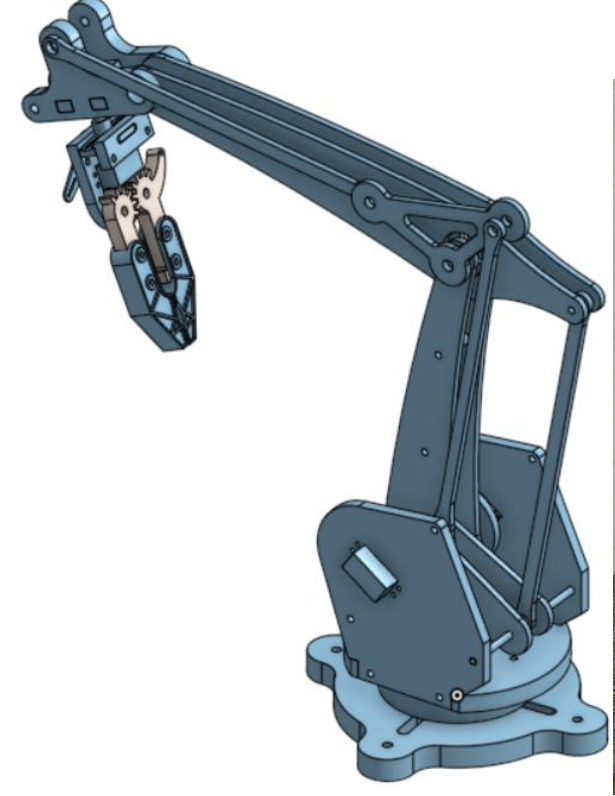

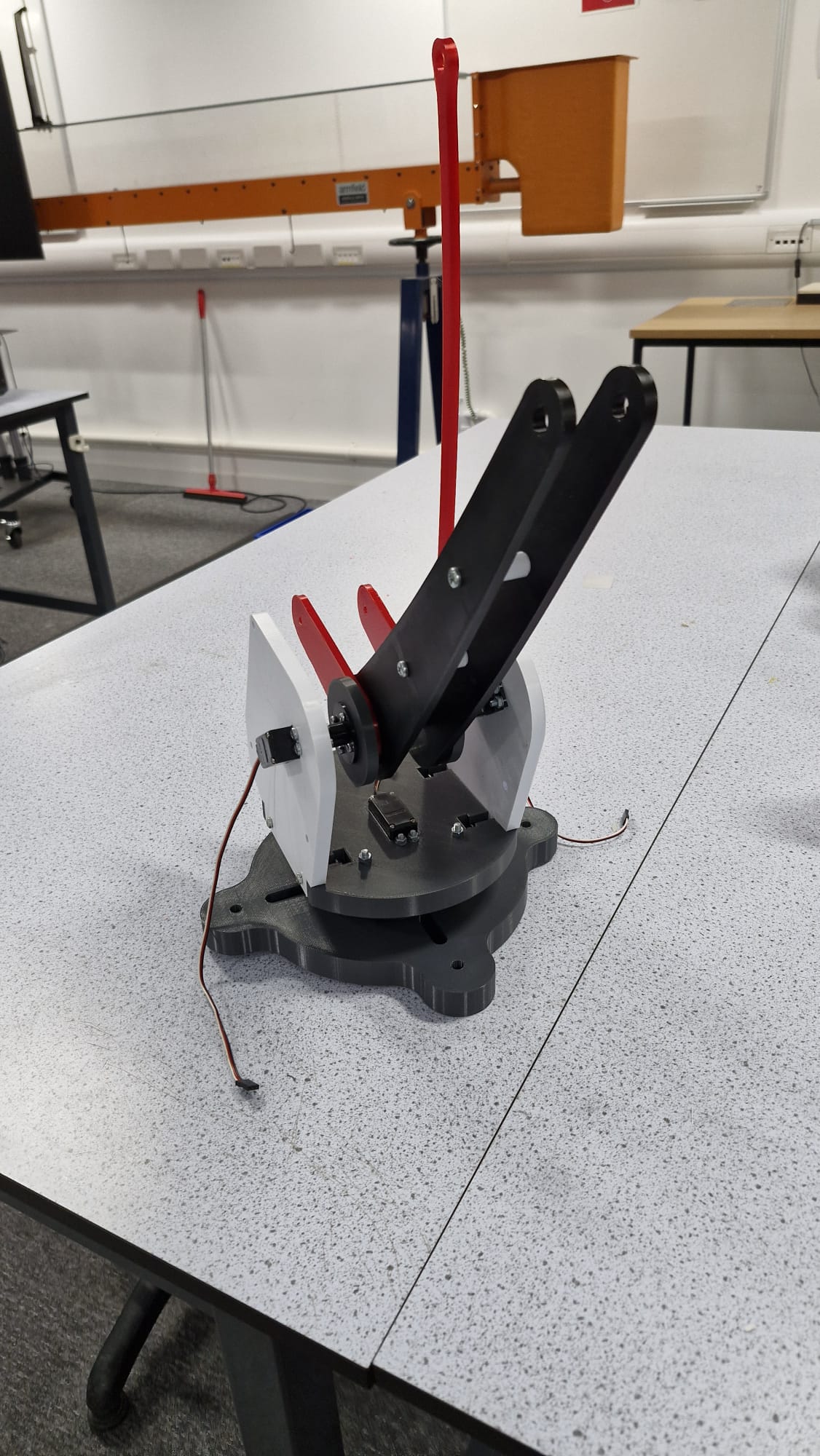

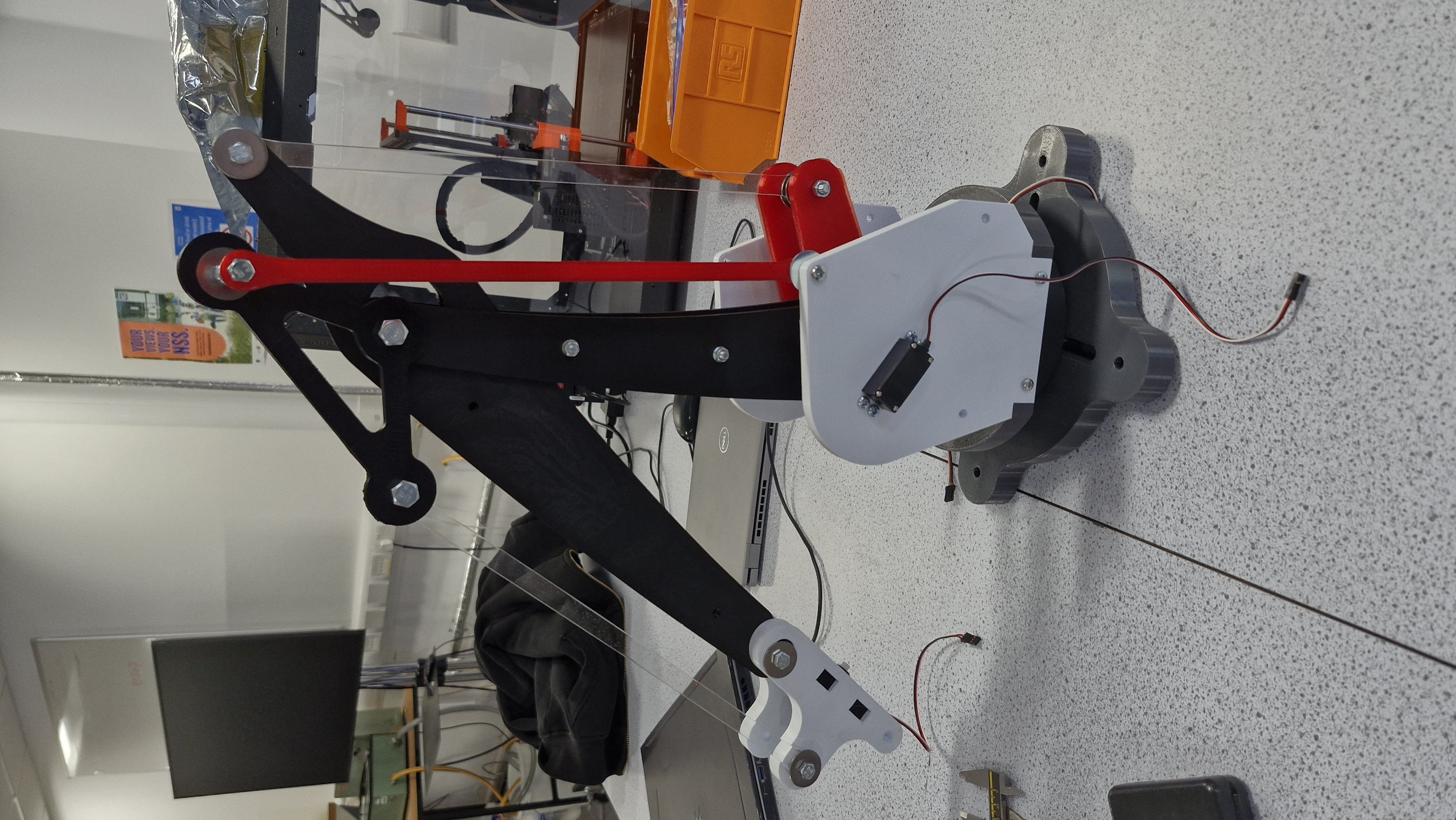

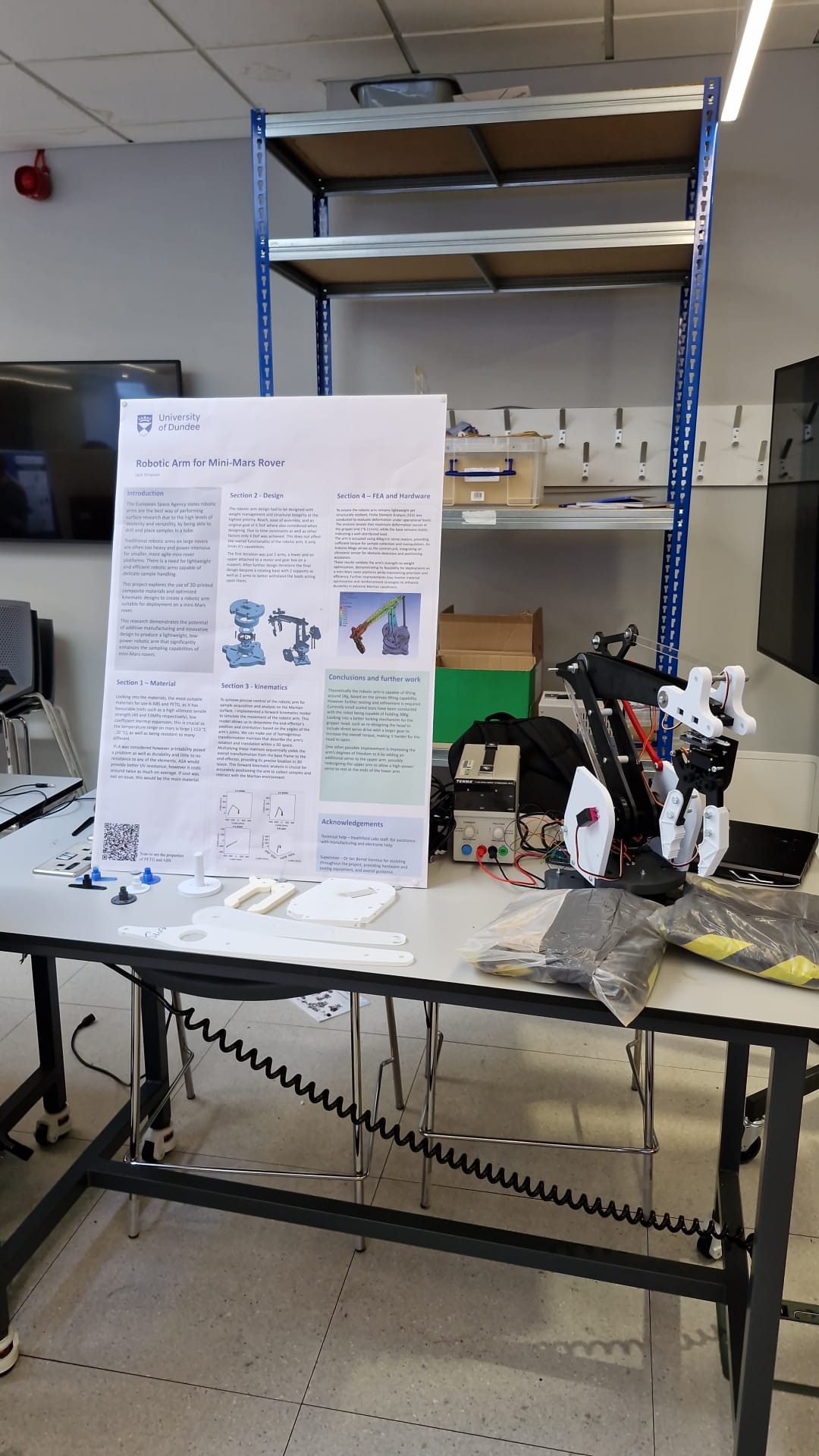

I set out to build a compact, lightweight robotic arm for a mini-Mars rover that could perform sample acquisition within mission-style mass and power limits. From requirements of ≥1 kg payload and ≤5 kg arm mass, I developed a multi-joint design in CAD, validated reach and motion using MATLAB forward kinematics with Denavit–Hartenberg parameters, and sized/verified the structure in ANSYS Workbench under worst-case loads.

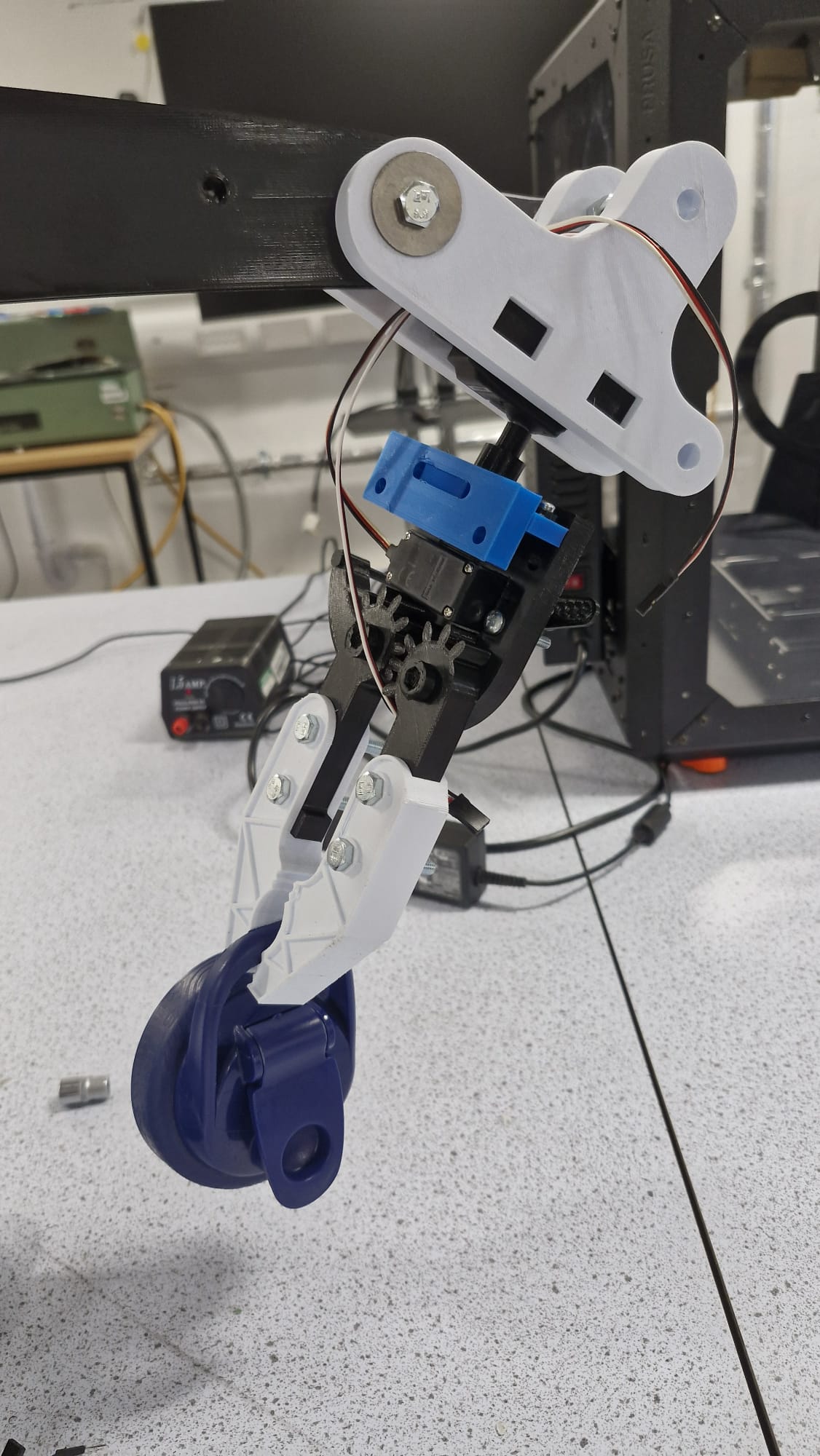

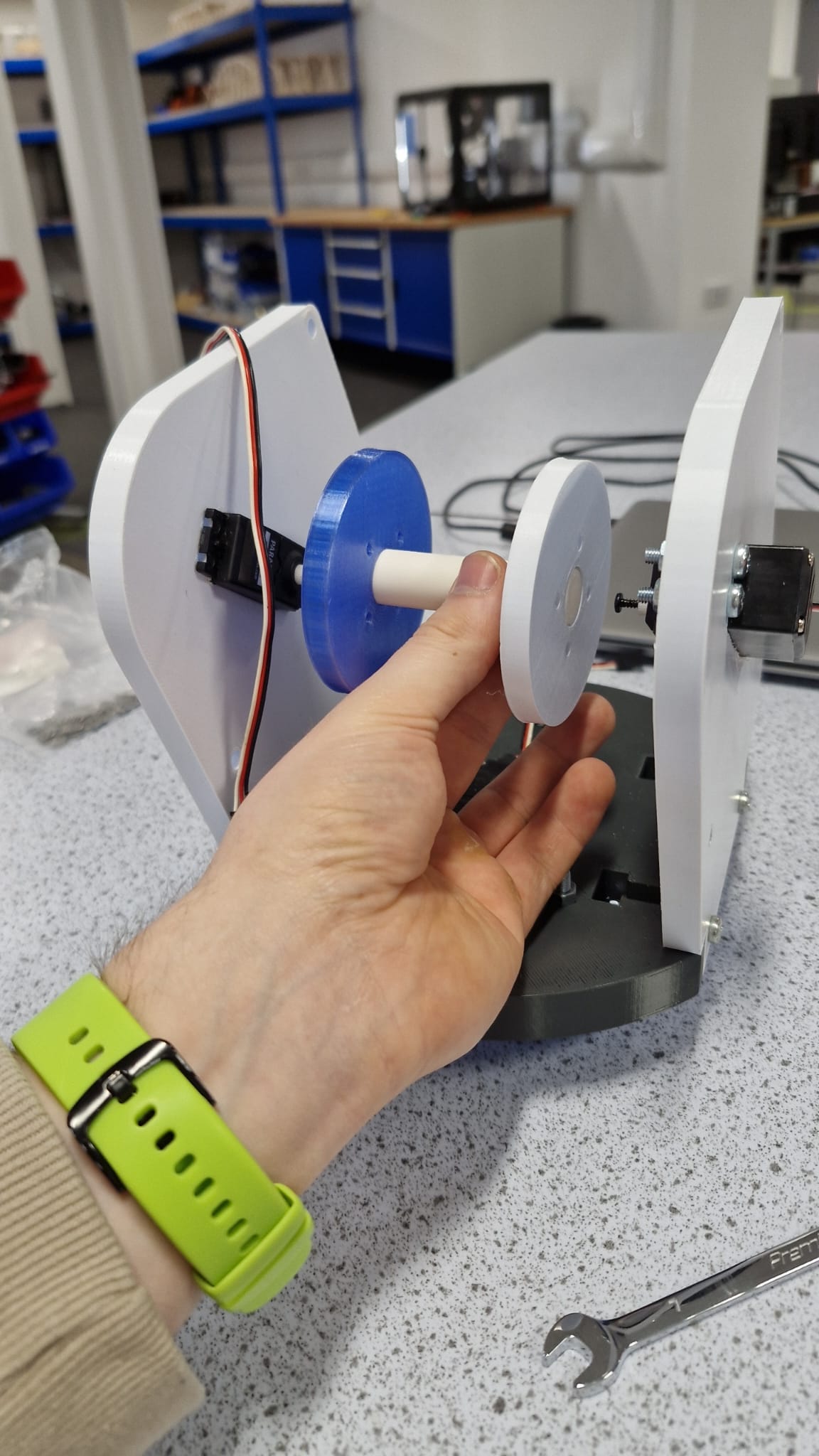

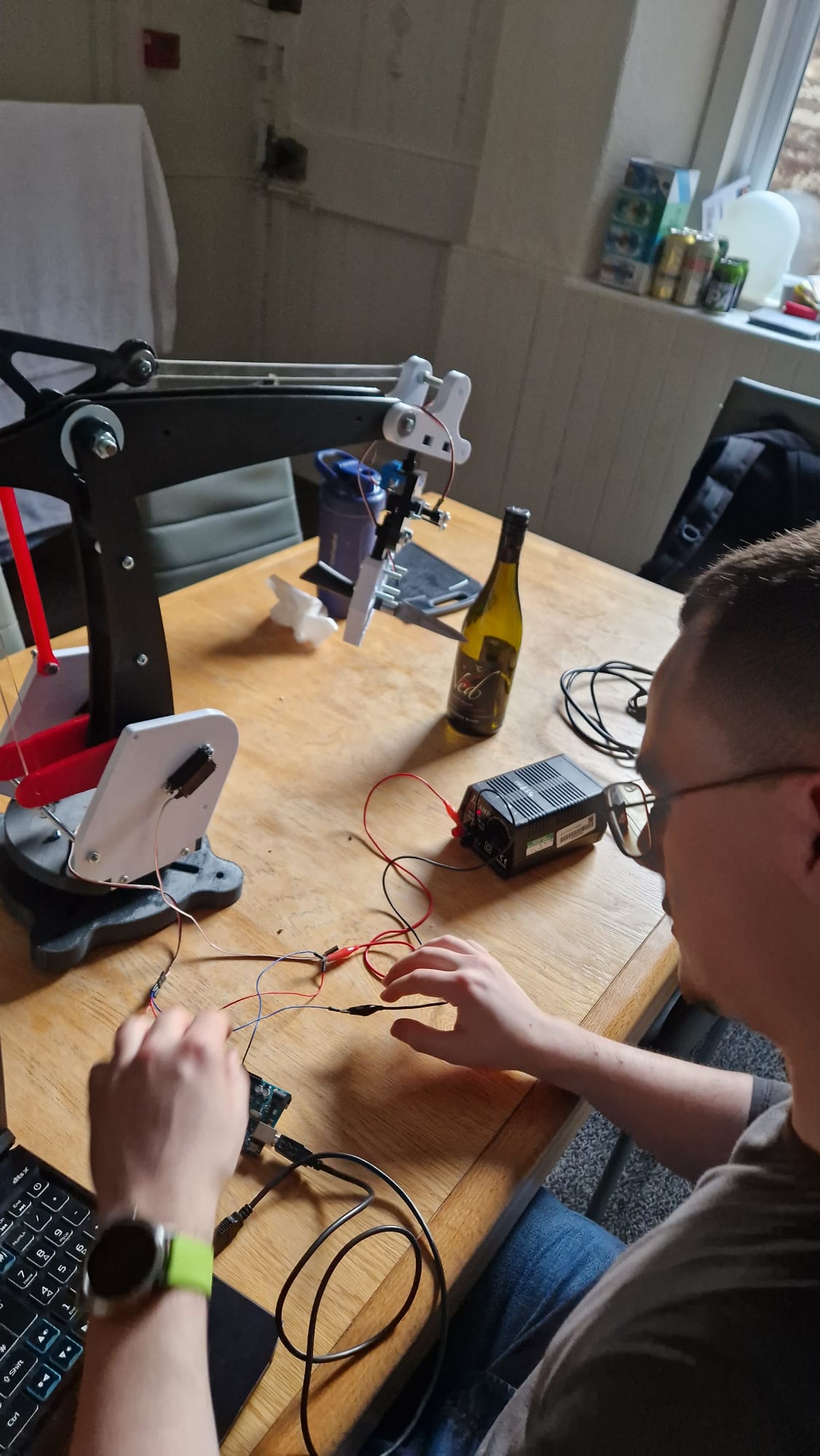

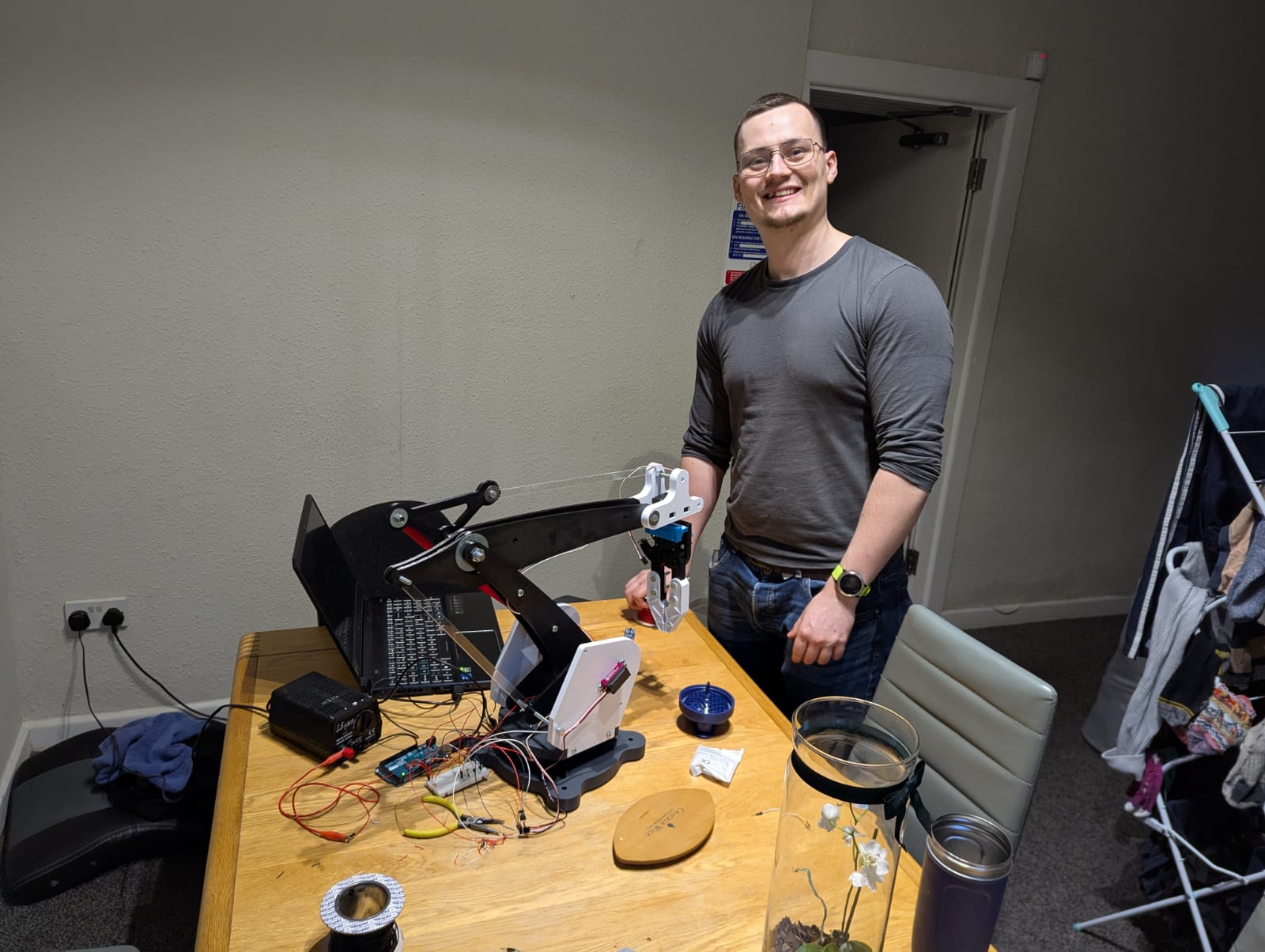

The arm was fabricated via FDM in PETG and ABS with part-specific infill/orientations to maximise stiffness-to-weight, then assembled with friction-fit and bolted joints. Control runs on an Arduino Mega 2560 with an ultrasonic sensor enabling proximity-based gripping. Bench tests confirmed a 1 kg lift at full extension with a final arm mass of 2.25 kg, meeting both targets; the main limitation was the gripper mechanism, informing the next iteration. Planned upgrades include inverse kinematics, full autonomy, higher payload, and improved environmental resilience for Mars-analog use.

Process

- Design & simulation: Onshape and Solidworks for CAD; forward kinematics in MATLAB using Denavit–Hartenberg parameters to validate reach and motion; structural verification via ANSYS Workbench FEA under simulated loads.

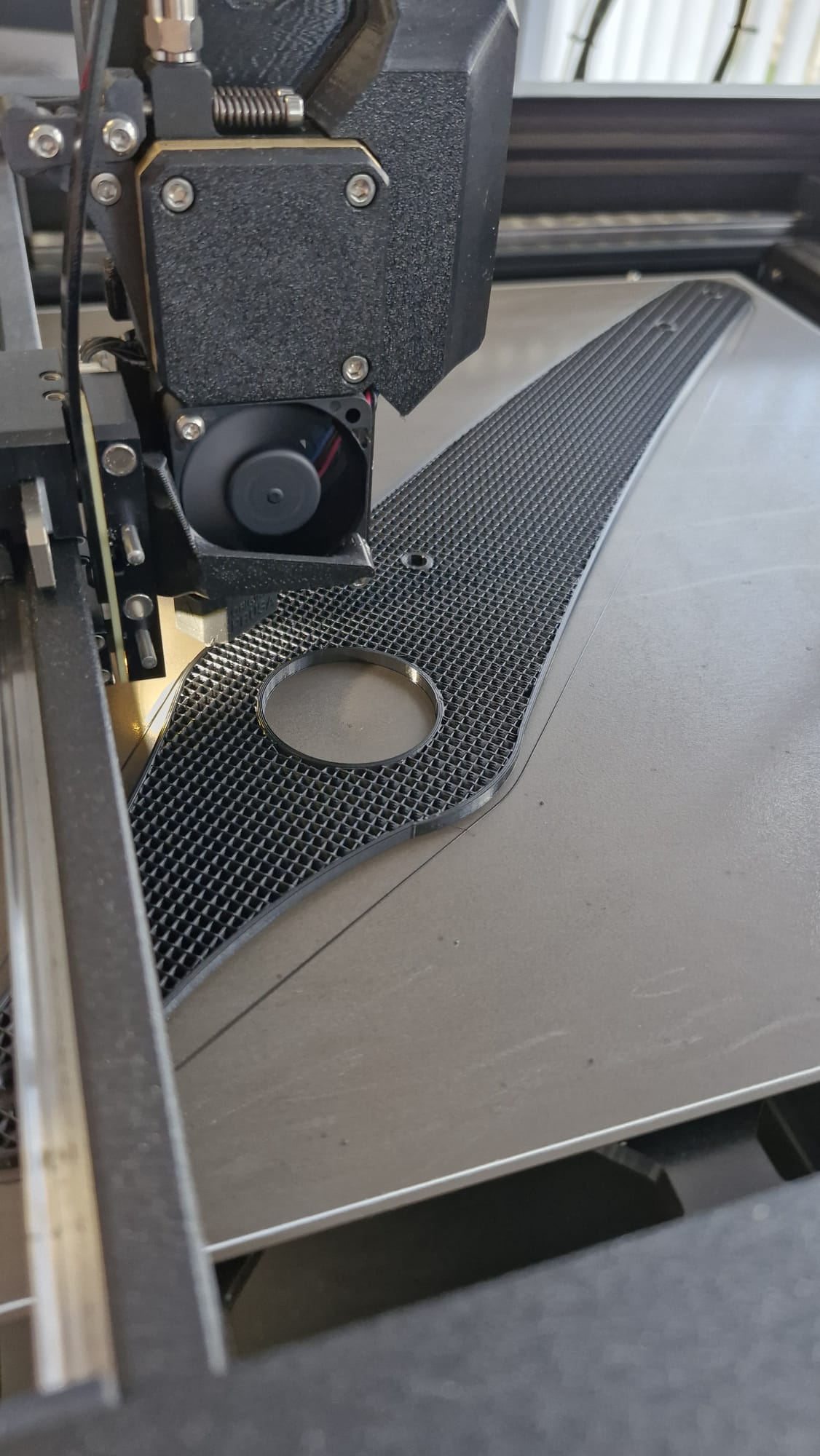

- Manufacturing: FDM 3D printing in PETG and ABS with part-specific infill/orientations to optimise strength-to-weight. Printed mainly on Prusa MK3/MK4/XL, with selected parts on a Stratasys F170 (Heathfield labs).

- Control & autonomy (v1): Arduino Mega 2560 with an HC-SR04 ultrasonic sensor for proximity-based gripping; friction-fit and bolted assemblies with post-print refinements for tolerances.

Outcomes

- Performance: Demonstrated lift of 1 kg at full extension; arm mass 2.25 kg.

- Validation: MATLAB forward-kinematics modelling confirmed reachable workspace; FEA verified structural performance under expected loads.

- Limitation found: Gripper open/close mechanism constrained throughput; captured as a redesign action. Weak point at "wrist"; possible design of a clutch.