Overview

I analysed and optimised a spanner/wrench in ANSYS Workbench under a 1000 N load, comparing Ti-6Al-4V with 316 stainless steel to guide material selection and lightweighting. I imported the university-provided geometry, set boundary conditions (fixed at the head, force at the handle), and ran a mesh study before evaluating deformation, von Mises stress and strain. I then performed explicit-dynamics tensile tests on dog-bone samples to understand failure behaviour, and used topology/response-surface exploration to identify material-removal opportunities while maintaining performance. Results showed titanium offered the best overall balance of strength, stiffness-to-weight, and durability for this application. Peak stresses concentrated near the handle end; titanium reached ~1018 MPa in tensile testing before failure vs ~999 MPa for 316, with steel showing higher ductility. The study closed with mass-retention trials (50% and 25%) and recommendations for geometry tweaks and further validation.

Process

- Brief & setup: 3D FEA of a wrench at 1000 N; import given geometry, vary thickness, define materials, apply BCs, and validate mesh quality.

- Material comparison: Modelled Ti-6Al-4V and 316 stainless steel based on strength/ductility targets; anticipated titanium’s higher tensile performance.

- Boundary conditions: Fixed support at the head; 1000 N load at the handle to replicate usage and prevent rigid-body modes.

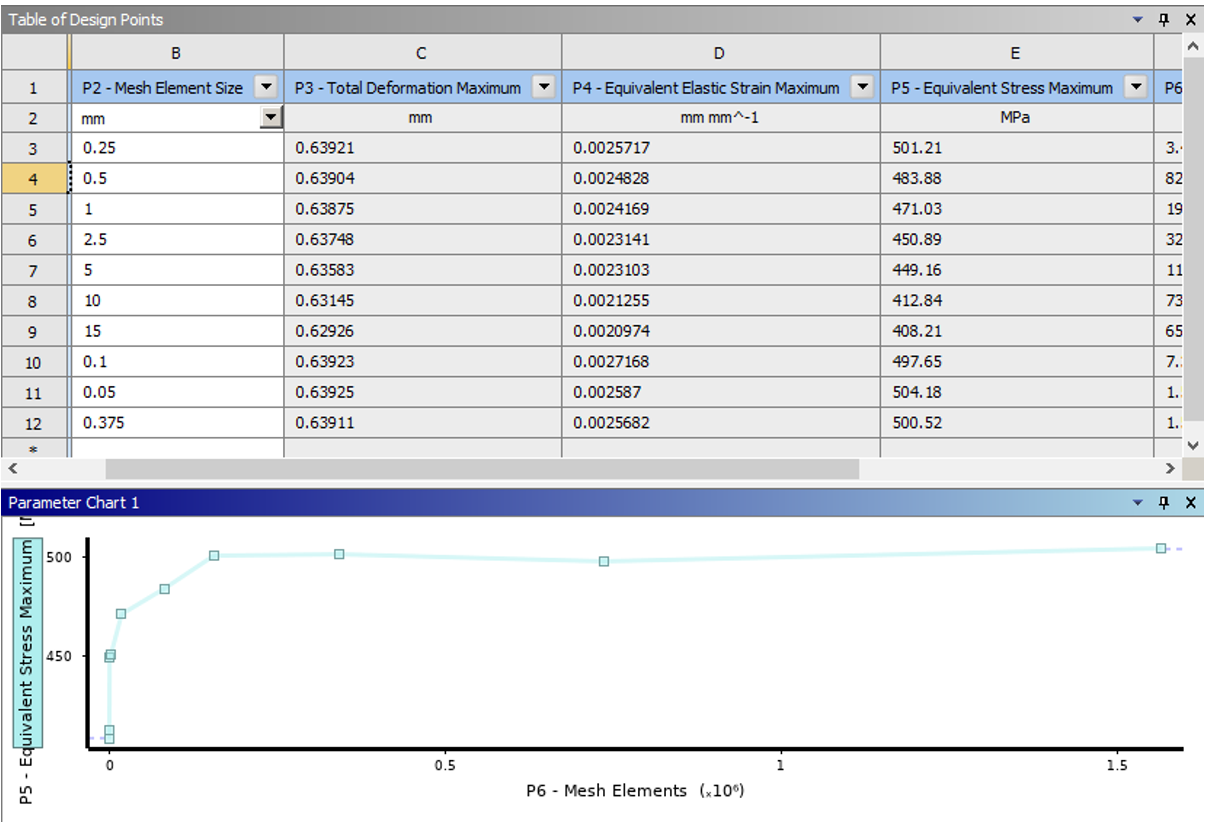

- Meshing & convergence: Started around 1 mm element size; parametric study of element size vs max stress to find convergence.

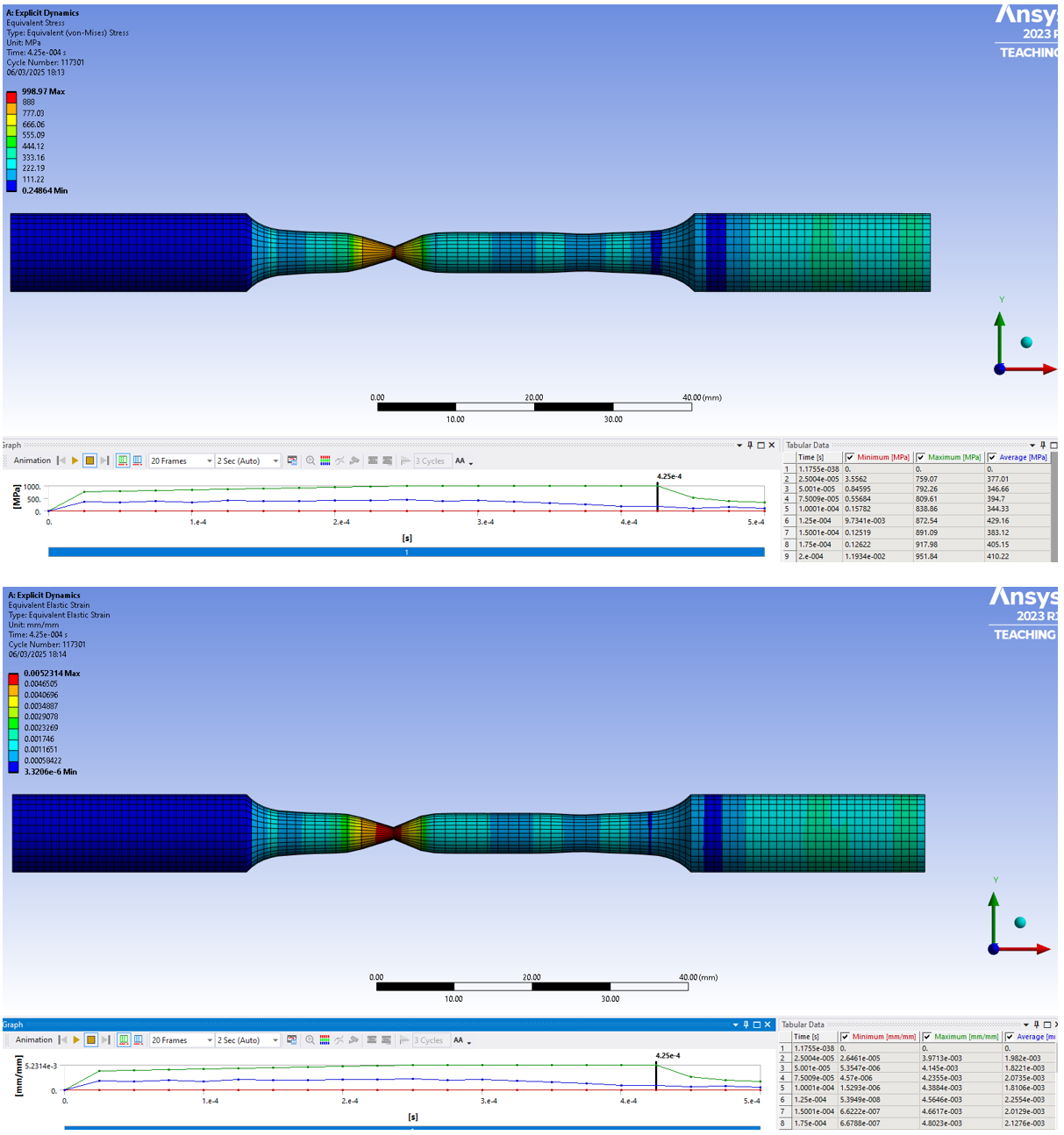

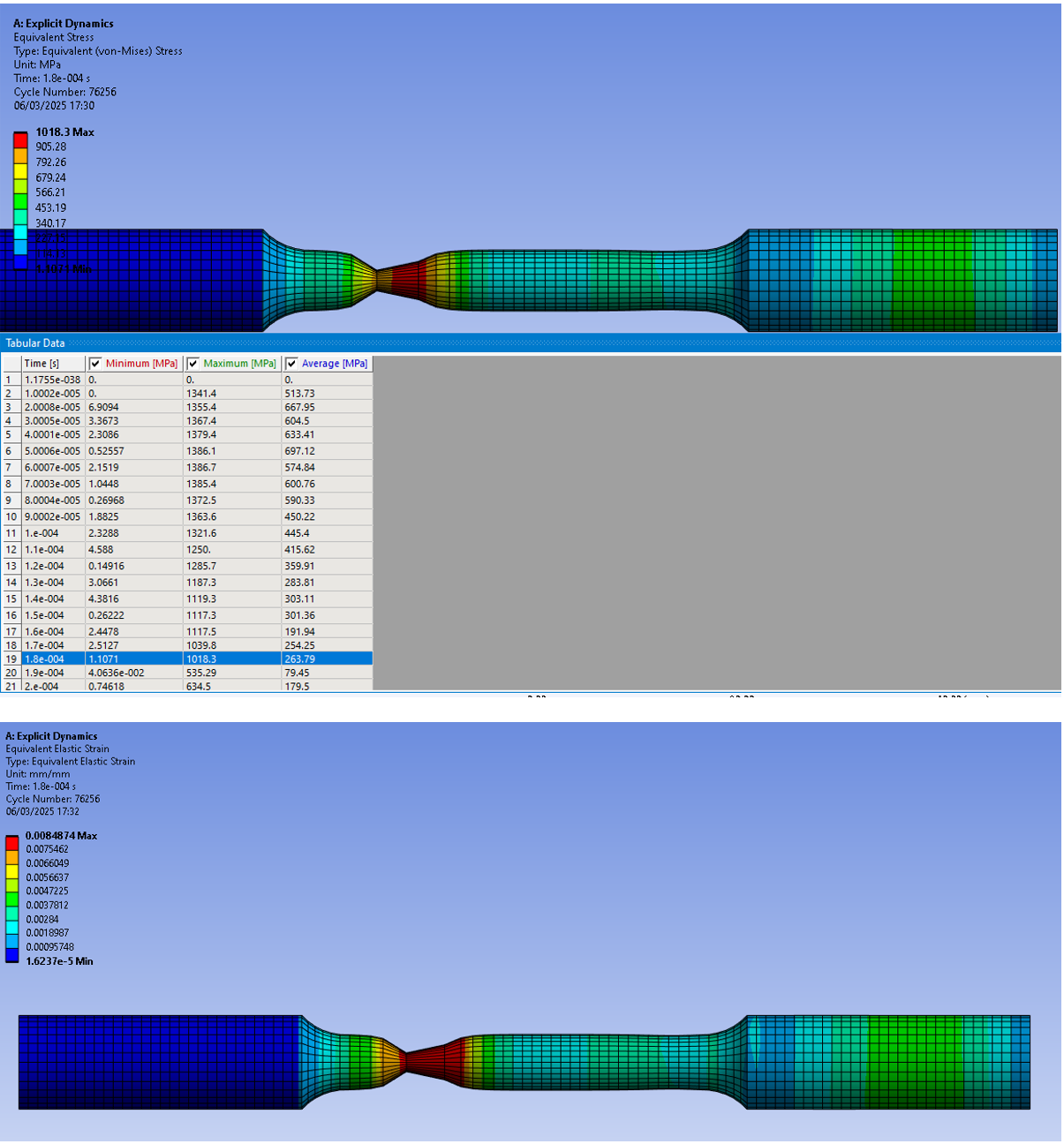

- Analyses: Static structural for deformation/stress/strain; explicit dynamics tensile tests on dog-bone samples with end displacement to failure.

- Design exploration: Sensitivity/response-surface work and topology-style optimisation on the titanium model with 50% and 25% mass-retention runs.

Outcomes

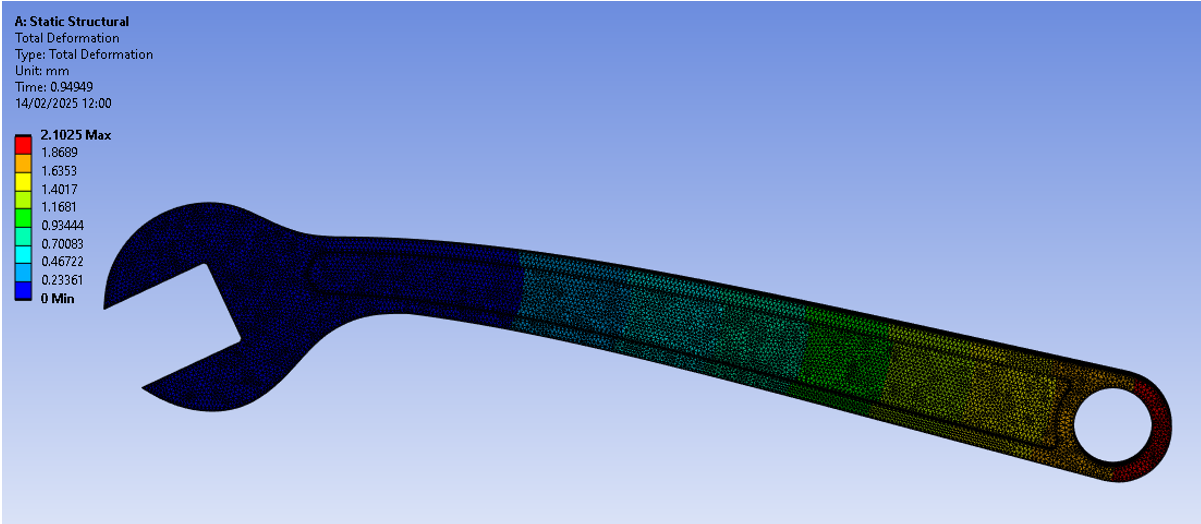

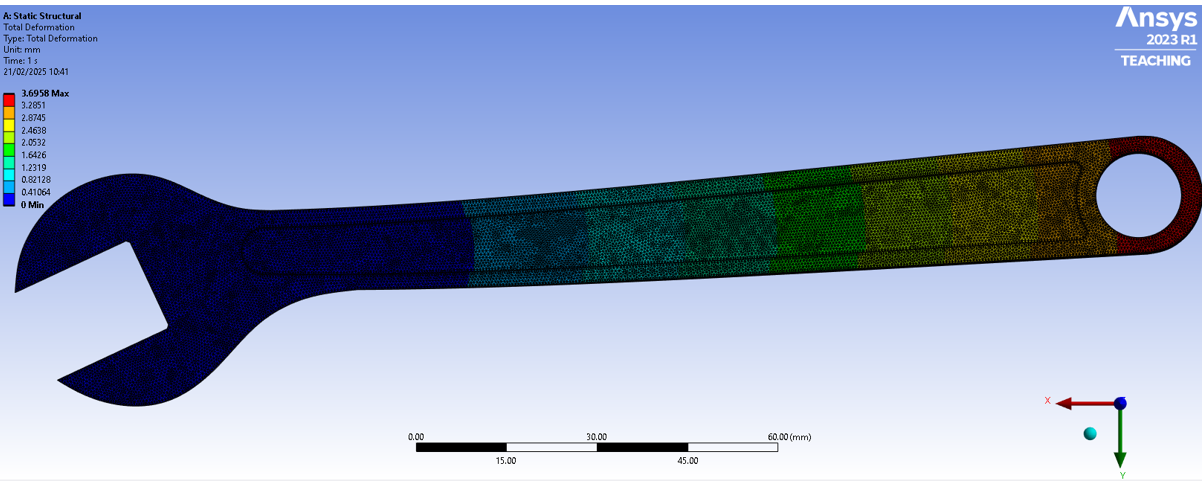

- Stress & deformation: Max stress localised near the end of the handle (~506 MPa); titanium deformed ~3.69 mm vs ~2.1 mm for 316 (consistent with lower E-modulus).

- Material behaviour: In tensile tests, Ti-6Al-4V ~1018 MPa max stress before failure; 316 SS ~999 MPa, with higher strain/ductility in steel.

- Recommendation: Titanium selected for the most favourable performance balance under the brief’s loading, with targeted material removal feasible per optimisation results.

- Next steps: Validate with physical testing; explore alternative geometries, added thickness in hot-spot regions, and additional materials/heat-treats.